- Whatsapp: 0086-15537166222

- Email: sinostar@cndiamondtech.com

Industrial-Grade Wet Diamond Concrete Core Drill Bits for Construction

Cutting Purpose:

Cured concrete, reinforced concrete ( #8 rebar and blow), precast concrete block, stone, asphalt etc. Water supply is a must.

Advantages:

- Precision: Creates clean, accurate holes with smooth edges.

- All these diamond segments are built with high grade diamonds of high concentration which ensures its cutting efficiency & durability in cutting

- laser welding technology prevent segments loss in rebars and tension cable coring.

- Different thread are avialble for fitting most hand held core drills or core drill rigs

- Effective length 16” with big coring depth , bit extension can be offered upon request

- Factory bulk supply, quality and shipping on time guarantee

- 1/2″-14″ diameters are available

High-Performance Wet Diamond Concrete Core Drill Bits

Simply as the name implies, our concrete core drill bits are with premium quality and used for drilling holes in various types of concrete and masonry materials, which requires a water supply for coring operation. All these concrete core bits are with effective length of14″/ 16”(400/450mm), longer length as 1000mm-1500mm are available upon request. Hub can be of 1-1/4”UNC, 1/2 BSP, M42, 5/8”-11, CR128 etc.

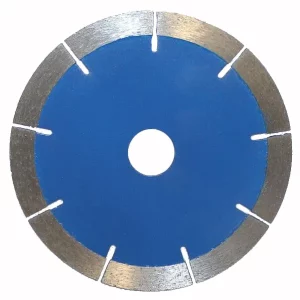

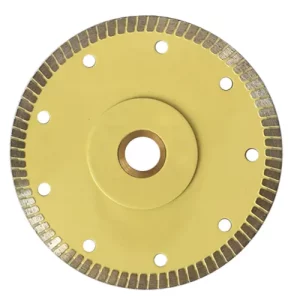

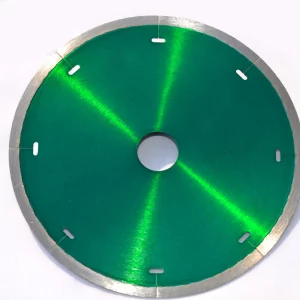

And we offer different kinds of segments for your options: flat segment type, V-segment type, sharp segment etc. One stands for its durability and the other two kinds stand for its excellent cutting speed. Both types are very mature and welcomed products on the market.

Sizes of Our Concrete Core Drill Bits :

| Dia. | Effective Length | Seg.No. | Roof teeth | Flat teeth | ||

| Seg.

Thickness |

Seg. Height | Seg.

Thickness |

Seg. Height | |||

| 1/2”(12mm) | 400mm | ring | / | / | / | 10mm |

| 9/16”(14mm) | 400mm | ring | / | / | / | 10mm |

| 5/8”(16mm) | 400mm | ring | / | / | / | 10mm |

| 3/4”(18mm) | 400mm | ring | / | / | / | 10mm |

| 13/16”(20mm) | 400mm | ring | / | / | / | 10mm |

| 7/8”(22mm) | 450mm | ring | / | / | / | 10mm |

| 15/16”(24mm) | 450mm | ring | / | / | / | 10mm |

| 1” (25mm) | 450mm | 3 | 3.5mm | 11mm | 3.8mm | 10mm |

| 1-1/4” (32mm) | 450mm | 4 | 3.5mm | 11mm | 3.8mm | 10mm |

| 1-1/2” (38mm) | 450mm | 4 | 3.5mm | 11mm | 3.8mm | 10mm |

| 2” (51mm) | 450mm | 5 | 3.5mm | 11mm | 4mm | 10mm |

| 2-1/2” (63mm) | 450mm | 6 | 3.5mm | 11mm | 4mm | 10mm |

| 3” (76mm) | 450mm | 7 | 3.5mm | 11mm | 4mm | 10mm |

| 3-1/4” (83mm) | 450mm | 8 | 3.5mm | 11mm | 4mm | 10mm |

| 3-1/2” (89mm) | 450mm | 8 | 3.5mm | 11mm | 4mm | 10mm |

| 4” (102mm) | 450mm | 9 | 3.5mm | 11mm | 4mm | 10mm |

| 4-1/4” (108mm) | 450mm | 10 | 3.5mm | 11mm | 4mm | 10mm |

| 5” (127mm) | 450mm | 11 | 3.5mm | 11mm | 4.2mm | 10mm |

| 6” (152mm) | 450mm | 13 | 4mm | 11mm | 4.3mm | 10mm |

| 7” (180mm) | 450mm | 14 | 4mm | 11mm | 4.3mm | 10mm |

| 8” (200mm) | 450mm | 15 | 4mm | 11mm | 4.5mm | 10mm |

| 10” (254mm) | 450mm | 18 | 4mm | 11mm | 5mm | 10mm |

| 12” (300mm) | 450mm | 20 | 4.5mm | 11mm | 5mm | 10mm |

| 14” (350mm) | 450mm | 25 | 4.5mm | 11mm | 5mm | 10mm |

| 16” (400mm) | 450mm | 28 | 4.5mm | 11mm | 5mm | 10mm |

other sizes are available upon request.

Primary Uses of Wet Diamond Core Drill Bits

- Drilling holes for plumbing, electrical conduits, and HVAC systems in concrete walls, floors, and ceilings.

- Creating openings for windows, doors, and ventilation systems.

- Cutting precise holes in reinforced concrete during building renovations or demolitions.

- Drilling holes for pipes and cables in concrete and masonry.

- Drilling holes in bridges, tunnels, and roads for structural analysis or utility installation

Factors that may affect the performance of the Concrete Core Drill bits

- Cutting Speed. Low RPM will cause longer time cutting, and very high RPM may make the segment polished and stop working. Proper speed will be necessary for the coring.

- Water supply. Too little water may cause burnt of the bits especially when cutting of steels while too much water may make the cutting slurry. Right amount supply of water can keep the cutting clean and efficient.

- Use right pressure during cutting. DO NOT push the bit too hard. A good driller can feel the right speed and right pressure and maintain them during use.

Related Products