- Whatsapp: 0086-15537166222

- Email: sinostar@cndiamondtech.com

ZMD-P High Purity Micron Diamond Powder Abrasive

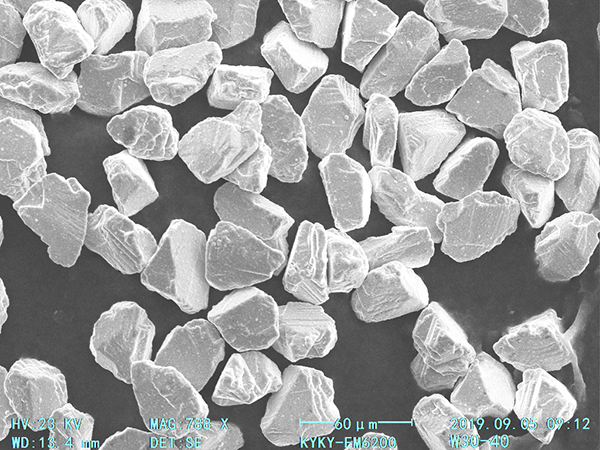

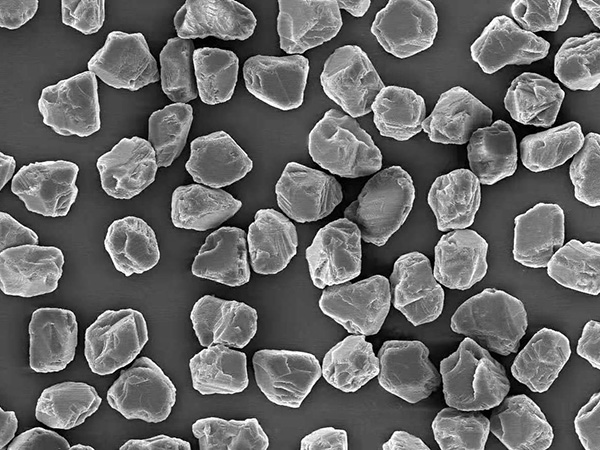

- High grade MBD diamond powder abrasiveswith good strength & purity is chosen as raw material

- Particle size of the micron diamond powder is in tight distribution

- Good thermal stability & wear resistance

- PPM level purity control

- Excellent surface cleanliness, which makes the diamond powder more conductive and good for sintering of poly crystalline diamond (PCD/PDC)

- Can also be used for metal bond, vitrified bond and electroplating tools.

Our ZMD-P series high purity micron diamond powder abrasive choose high grade MBD diamond as raw material. It is with super clean surface and those impurities are controlled to the ppm level. Narrow particle size distribution. The ZMD-P micron diamond powder abrasive is with good and stable dispersion and suspension ability whether for water-based and oil-based agent to ensure the grinding and polishing efficiency. Good wear resistance and thermal stability.

Application of ZMD-P High Purity Micron Diamond Powder Abrasive:

The high purity micron diamond powder abrasive can be used for sintering diamond poly crystalline diamond(PCD/PDC), diamond composite, metal bond grinding tools, vitrified bond and electroplating diamond tools etc.

Particle Size Available:

| AVAILABLE MICRON DIAMOND POWDER PARTICLE SIZE | |||

| China GB | International partical size (μm) | Japan Size | D50 (μm) |

| W0.25 | 0-0.25 | 60000 | 0.11-0.20 |

| W0.5 | 0-0.5 | 30000 | 0.20-0.30 |

| W1- | 0-1 | 20000 | 0.50-0.60 |

| W1 | 0.5-1 | 15000 | 0.60-0.80 |

| W1.5- | 0-2 | 13000 | 0.80-1.00 |

| W1.5 | 1-2 | 12000 | 1.10-1.30 |

| W2.5- | 1-3- | 10000 | 1.60-1.70 |

| W2.5 | 1-3 | 8000 | 1.70-1.90 |

| W2.5+ | 1-3+ | 7000 | 1.90-2.10 |

| W3- | 2-3 | 6500 | 2.20-2.60 |

| W3 | 2-4 | 6000 | 2.60-3.00 |

| W3.5 | 2-5 | 5000 | 3.10-3.40 |

| W5- | 3-5 | 4000 | 3.50-4.20 |

| W5 | 4-6 | 3500 | 4.40-5.00 |

| W7- | 4-8 | 3000 | 5.00-6.00 |

| W7 | 4-8+ | 2500 | 6.10-6.50 |

| W10- | 5-10 | 2000 | 6.50-7.30 |

| W10 | 6-12- | 1800 | 7.30-8.30 |

| W10+ | 6-12 | 1500 | 8.30-9.00 |

| W14- | 8-12 | 1500 | 9.10-10.50 |

| W14 | 8-16 | 1300 | 10.0-12.0 |

| W20- | 10-20 | 1200 | 12.5-15.0 |

| W20 | 12-22 | 1000 | 15-17 |

| W20+ | 15-25 | 800 | 18-20 |

| W28- | 20-30- | 700 | 20-23 |

| W28 | 20-30 | 600 | 23-26 |

| W28+ | 20-40 | 500 | 26-29 |

| W40- | 30-40- | 450 | 29-32 |

| W40 | 30-40 | 400 | 32-36 |

| W40+ | 35-45 | 350 | 37-41 |

| W50- | 40-50 | 320 | 41-45 |

| W50 | 40-60 | 300 | 45-50 |

Related Products