- Whatsapp: 0086-15537166222

- Email: sinostar@cndiamondtech.com

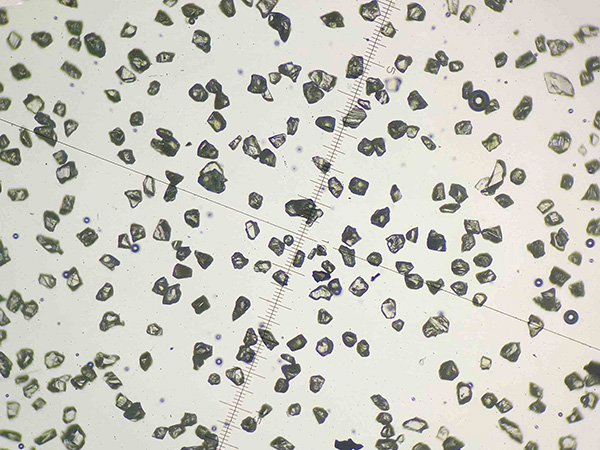

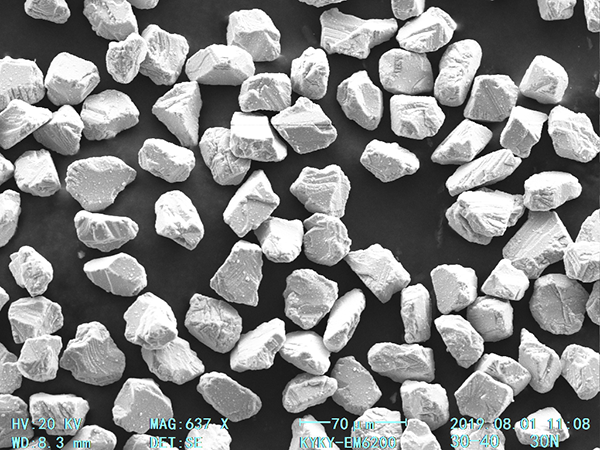

ZMD-PM Premium Precision MBD Micron Diamond Powder

Features of Precision MBD Micron Diamond Powder:

- Start with high grade MBD diamond powder as raw material

- The precision micron diamond powder is with consistent shape, and perform with high efficiency.

- Particle size of the micron diamond powder is in tight distribution.

- High purity– impurities of the micron diamond powder is less than 50ppm.

- Good strength and wear resistance.

Applications of Precision MBD Micron Diamond Powder :

- The precision diamond powder is used for precision grinding wheels & tools producing.

- The micron diamond powder can be used for making of metal bond diamond tools, vitrified bond diamond tools and electroplating diamond tools.

- The tools made by the precision MBD micron diamond powder are used for grinding, slicing, polishing & lapping of : precision machinery, precision ceramics, optical glass, sapphire &other precious stone, semi-conductor etc.

Particle Size Available:

| AVAILABLE MICRON DIAMOND POWDER PARTICLE SIZE | |||

| China GB | International particle size (μm) | Japan Size | D50 (μm) |

| W0.25 | 0-0.25 | 60000 | 0.11-0.20 |

| W0.5 | 0-0.5 | 30000 | 0.20-0.30 |

| W1- | 0-1 | 20000 | 0.50-0.60 |

| W1 | 0.5-1 | 15000 | 0.60-0.80 |

| W1.5- | 0-2 | 13000 | 0.80-1.00 |

| W1.5 | 1-2 | 12000 | 1.10-1.30 |

| W2.5- | 1-3- | 10000 | 1.60-1.70 |

| W2.5 | 1-3 | 8000 | 1.70-1.90 |

| W2.5+ | 1-3+ | 7000 | 1.90-2.10 |

| W3- | 2-3 | 6500 | 2.20-2.60 |

| W3 | 2-4 | 6000 | 2.60-3.00 |

| W3.5 | 2-5 | 5000 | 3.10-3.40 |

| W5- | 3-5 | 4000 | 3.50-4.20 |

| W5 | 4-6 | 3500 | 4.40-5.00 |

| W7- | 4-8 | 3000 | 5.00-6.00 |

| W7 | 4-8+ | 2500 | 6.10-6.50 |

| W10- | 5-10 | 2000 | 6.50-7.30 |

| W10 | 6-12- | 1800 | 7.30-8.30 |

| W10+ | 6-12 | 1500 | 8.30-9.00 |

| W14- | 8-12 | 1500 | 9.10-10.50 |

| W14 | 8-16 | 1300 | 10.0-12.0 |

| W20- | 10-20 | 1200 | 12.5-15.0 |

| W20 | 12-22 | 1000 | 15-17 |

| W20+ | 15-25 | 800 | 18-20 |

| W28- | 20-30- | 700 | 20-23 |

| W28 | 20-30 | 600 | 23-26 |

| W28+ | 20-40 | 500 | 26-29 |

| W40- | 30-40- | 450 | 29-32 |

| W40 | 30-40 | 400 | 32-36 |

| W40+ | 35-45 | 350 | 37-41 |

| W50- | 40-50 | 320 | 41-45 |

| W50 | 40-60 | 300 | 45-50 |

Related Products