- Whatsapp: 0086-15537166222

- Email: sinostar@cndiamondtech.com

ZMD-M High Strength MBD Micron Diamond Powder

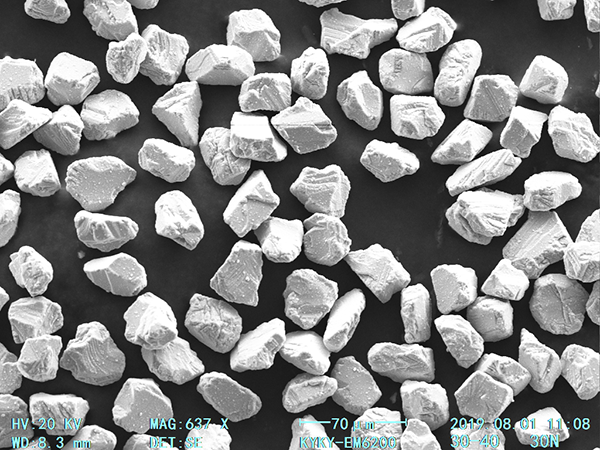

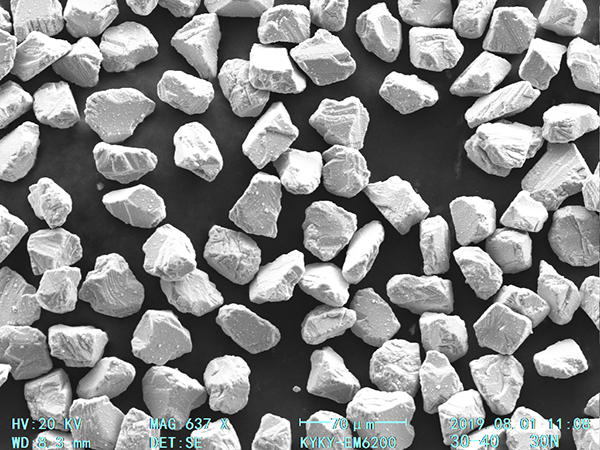

- We choose metal bond synthetic diamond powder with uniform shape, high impact strength and good thermal stability as raw material

- The high strength MBD micron diamond powder is with regular and blocky shape

- Particle size of the micron diamond powder is in tight distribution

- Excellent powder dispersivity

- Low impurities

- Recommended for semi-conductor like Si wafers, optical glass, precision bears, fine ceramics & sealing processing

ZMD-M high strength MBD micron diamond powder is deprived from HPHT mono-crystalline diamond of metal bond grade with uniform shapes, low impurities and high impact resistance. Accompanied by strict controlled processing, the micro diamond powder shows with tightly controlled size, shape and surface.

Application of ZMD-M High Strength MBD Micron Diamond Powder:

It is featured with blocky shape, high purity, good thermal stability and impact resist. And is recommended for metal bond diamond tools making. And the tools is used for a wide variety of grinding, polishing or lapping process. It can do semi-conductor like Si wafers, optical glass, precision bears, fine ceramics & sealing.

Particle Size Available:

| AVAILABLE MICRON DIAMOND POWDER PARTICLE SIZE | |||

| China GB | International Particle size (μm) | Japan Size | D50 (μm) |

| W0.25 | 0-0.25 | 60000 | 0.11-0.20 |

| W0.5 | 0-0.5 | 30000 | 0.20-0.30 |

| W1- | 0-1 | 20000 | 0.50-0.60 |

| W1 | 0.5-1 | 15000 | 0.60-0.80 |

| W1.5- | 0-2 | 13000 | 0.80-1.00 |

| W1.5 | 1-2 | 12000 | 1.10-1.30 |

| W2.5- | 1-3- | 10000 | 1.60-1.70 |

| W2.5 | 1-3 | 8000 | 1.70-1.90 |

| W2.5+ | 1-3+ | 7000 | 1.90-2.10 |

| W3- | 2-3 | 6500 | 2.20-2.60 |

| W3 | 2-4 | 6000 | 2.60-3.00 |

| W3.5 | 2-5 | 5000 | 3.10-3.40 |

| W5- | 3-5 | 4000 | 3.50-4.20 |

| W5 | 4-6 | 3500 | 4.40-5.00 |

| W7- | 4-8 | 3000 | 5.00-6.00 |

| W7 | 4-8+ | 2500 | 6.10-6.50 |

| W10- | 5-10 | 2000 | 6.50-7.30 |

| W10 | 6-12- | 1800 | 7.30-8.30 |

| W10+ | 6-12 | 1500 | 8.30-9.00 |

| W14- | 8-12 | 1500 | 9.10-10.50 |

| W14 | 8-16 | 1300 | 10.0-12.0 |

| W20- | 10-20 | 1200 | 12.5-15.0 |

| W20 | 12-22 | 1000 | 15-17 |

| W20+ | 15-25 | 800 | 18-20 |

| W28- | 20-30- | 700 | 20-23 |

| W28 | 20-30 | 600 | 23-26 |

| W28+ | 20-40 | 500 | 26-29 |

| W40- | 30-40- | 450 | 29-32 |

| W40 | 30-40 | 400 | 32-36 |

| W40+ | 35-45 | 350 | 37-41 |

| W50- | 40-50 | 320 | 41-45 |

| W50 | 40-60 | 300 | 45-50 |

Related Products